The laboratory is equipped with measuring tools from the renowned Mahr company. In addition to the basic caliper, micrometric and sensor tools, students have the opportunity to learn about highly accurate measuring instruments.

The scientific and research offer includes the following devices:

| The device | Photograph | Description of technological capabilities | Contact person |

| Optical microscope 3Dsystem infiniteFocus - Alicona |

Optical method using a white light laser. Roughness testing according to ISO 4287 standards for tactile measurements, and the new ISO 25178 roughness standard for optical methods, and: - profile - shape - qualitative analysis of the condition - surface (erosion, corrosion, grain shape) - failure cause analysis (breakthroughs) - analysis of machining tools (blade wear, material migration) |

Jacek Misiura, M.Sc. Eng. | |

| INEXIV optical microscope |  |

INEXIV optical microscope with an additional Renishaw contact probe, which allows you to combine contact and non-contact measurements in one measurement plan. The creation of programs takes place during the programming of the trainer. Focusing is performed automatically using the Vision AF or Laser AF system. The AF laser also allows you to carry out measurements in the Z axis. The measuring range of the microscope is 250 x 200 x 200mm. The optical system magnifies the screen from 12 to 120x. Measurement results are given with an accuracy of 0.1 μm. |

Jacek Misiura, M.Sc. Eng. |

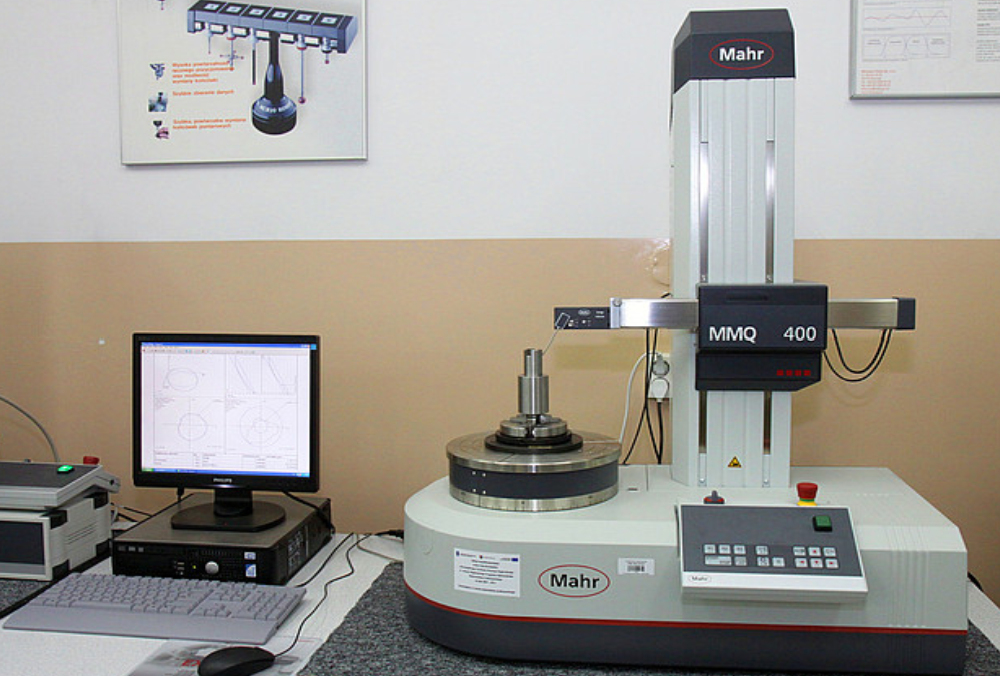

| MMQ 400 system for measuring deviations in shape and position |  |

Contact measurement method. Measurement and analysis of macro and micro deviations of shape and position. Enables the measurement of shape and position deviations according to DIN/EN/ISO, such as roundness, straightness, parallelism, etc. |

Jacek Misiura, M.Sc. Eng. |

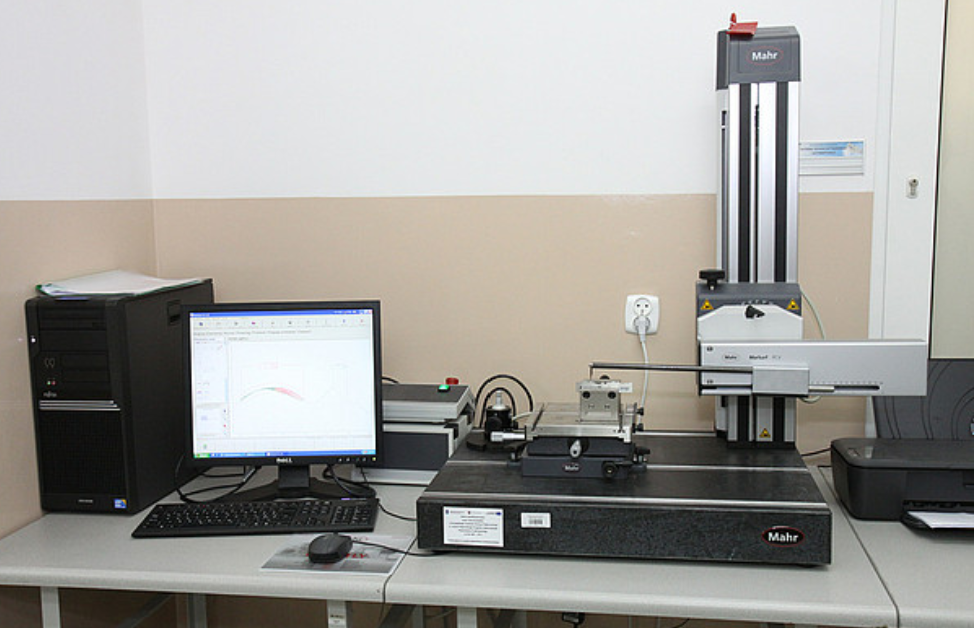

| XR 20 surface roughness, waviness and topography measurement system |  |

Contact measurement method. Analysis and measurement of surface roughness, waviness and geometric structure of the SGP surface. |

Jacek Misiura, M.Sc. Eng. |

| XC 20 contour measuring system |  |

Contact measurement method. Very fast and accurate measurement of contours and profiles from an element and its analysis according to DIN/EN/ISO standards. |

Jacek Misiura, M.Sc. Eng. |

|

Portable measuring arm |

|

Contact and laser measurement method. Analysis and measurements of element geometry, and creation of free-form surfaces and curves directly from element geometry using the point method. Application in research: reverse engineering, collecting points, curves and planes, laser scanning of elements. |

Paweł Turek, D.Sc. Eng. |

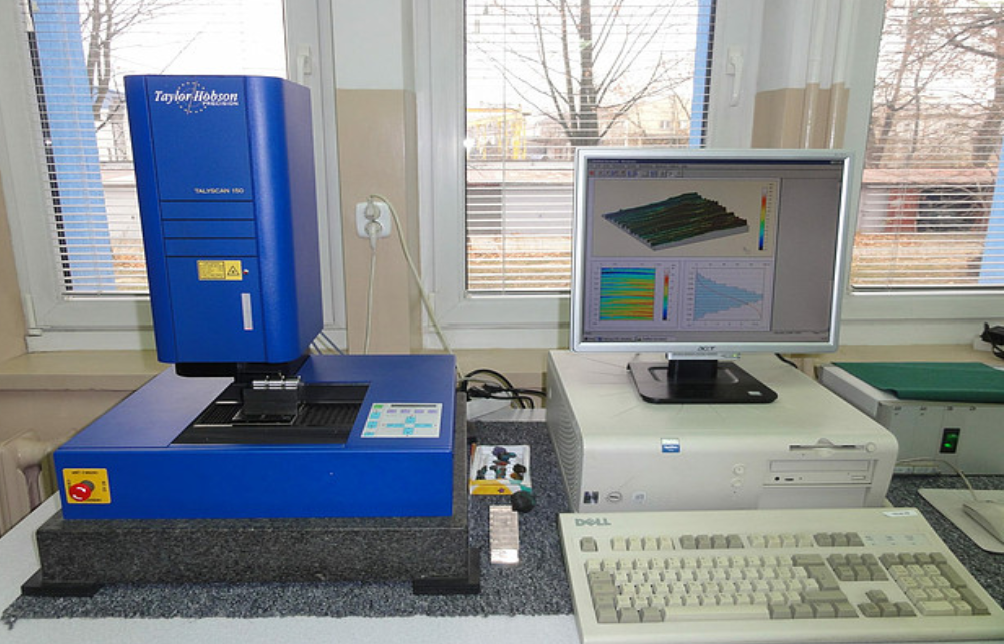

| TalyScan 150 3D profilometer |  |

It enables surface roughness measurements to be carried out using the contact and non-contact method. The vertical resolution is 0.6 μm when measuring with a stylus and 1 μm when measuring with a laser. |

Jacek Misiura, M.Sc. Eng. |