The Laboratory of technological machines carries out scientific and development research, didactic classes with students, and the implementation of engineering and master theses. As part of the classes conducted in the laboratory, students learn about the construction, standard and special equipment, technological possibilities, operation and programming of technological machines.

The scientific and research offer includes the following devices:

| The device | Photograph | Description of technological capabilities | Contact person |

| MC 726 MT / STAMA Mill/Turn 5-axis Machine |  |

A machine for multi-axis complete and multi-tasking turning, milling and drilling of workpieces from 6 sides. It is equipped with a bar feeder, counter-spindle for interception and an automatic receiver of workpieces. |

|

| CNC multi-axis milling center assisted by ultrasonic technology - Sauer Ultrasonic 20 linear |  |

The machine is designed for 3D machining of surfaces of any shape, drilling holes, making threads, planning and grinding in hard materials such as stainless steels, sintered carbides, glass, porcelain, etc. | Artur Szajna, M.Sc. Eng |

|

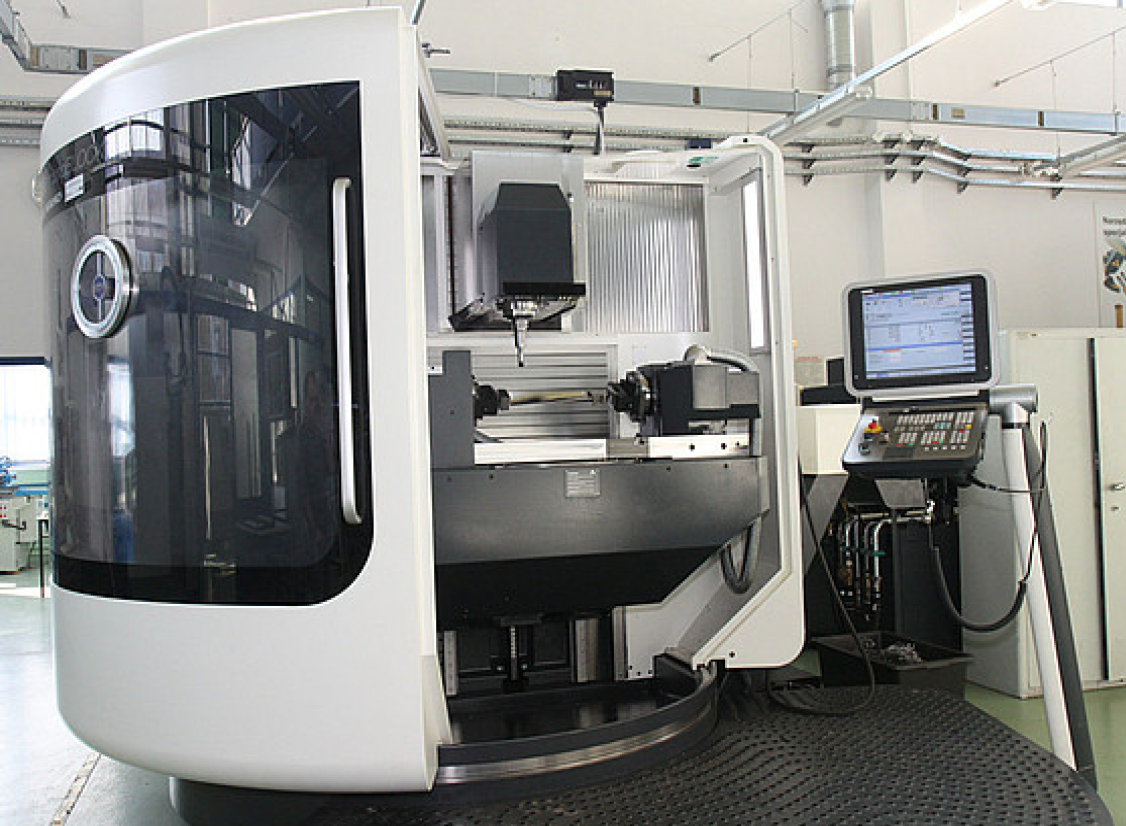

DMU 100 monoBLOCK CNC universal milling machine |

|

Milling center for 5-axis continuous machining of complex surfaces found in the aviation industry, e.g. rotors and blades made mainly of difficult-to-machine materials (nickel, titanium alloys, etc.). The kinematics of the machine tool provides simultaneous 5-axis milling of curvilinear surfaces in two variants: variant 1: simultaneous 5-axis milling in the system rotary head (rotary axis B) - rotary table (rotary axis C), variant 2: simultaneous 5-axis milling in the system rotary head (rotary axis B) - rotary horizontal axis A (two dividing head NC). |

Michał Gdula, D.Sc. Eng. |

| 5-axis Precision Machining Centre HSC 55 linear |  |

Milling center for 5-axis continuous machining of complex surfaces and thin-walled HSC elements (with high cutting speeds and high feeds) found in the aviation industry, e.g. rotors, bodies, wing structure elements made mainly of aluminum alloys. The kinematics of the machine tool provides simultaneous 5-axis milling of curvilinear surfaces - simultaneous 5-axis milling in the NC rotary table system (rotary axis A and C). |

Marcin Płodzień, D.Sc. Eng. |

|

Precision CNC Tool Grinder MICHAEL DECKEL CNC |

|

Universal grinding machine for cutting tools with five numerically controlled axes for making and sharpening cutters, drills, step drills, stepped tools, reamers, taps, woodworking tools, shaped plates, shaped knives or other shaped tools. |

Marcin Sałata, M.Sc. Eng. |

| Geibel & Hotz FS640Z surface and profile grinding machine |  |

A grinding machine with orbital grinding cycles, plunge grinding cycles and other specific machining cycles. Equipped with a programmed roller for shaping the outline of the grinding wheel and an advanced system of measuring sensors necessary to perform comprehensive process tests, including piezoelectric force gauges, vibration sensor, acoustic emission sensor and active dimension control system. |

Łukasz Żyłka, D.Sc. Eng. |

|

Geibel & Hotz RS600C CNC cylindrical grinding machine |

|

A grinding machine with workpiece grinding cycles: plunge grinding in the x-axis, optionally with short-stroke oscillation, plunge grinding in the z-axis, longitudinal grinding with in-feed at turning points (also for spherical parts), multiple plunge grinding in the x-direction with overlap , profile grinding (deep grinding of any contours with a rounded grinding wheel), oscillation at an angle (grinding at an angle with an oblique or oblique grinding wheel), oblique-plunge grinding at any angle, oscillating grinding in the X direction, deep grinding in the Z direction (up to quick machining and high surface roughness of cylindrical workpieces). It is equipped with measuring systems enabling a full range of measurements of the grinding process output quantities. |

Paweł Sułkowicz, D.Sc. Eng. |

|

Koepfer 200 CNC gear hobbing machine |

|

Milling machine for machining cylindrical gears as well as worm wheels and straight worms. |

Jarosław Buk, M.Sc. Eng. |